China Recorder Molds Manufacturer, Supplier, Factory

The key to our success is "Good Merchandise High-quality, Reasonable Selling price and Efficient Service" for Recorder Molds, Should further more info be required, remember to call us at any time!

Recorder Molds, we've got complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, specialist sales service team. With all these advantages, we are gonna create"the reputable international brand of nylon monofilaments", and spreading our goods to every corner of the world. We have been keep moving and try our best to serve our customers.

Hot Products

Plastic Forks Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Plastic forks molding. P&M are both a brand and a factory, with thousands of types of products, with high-quality service and quality as the first, Our main products is design and manufacturing of plastic mold, plastic product, metal product, We are suppliers of ice cream spoon plastic ,we provide Plastic forks molding services. Also, we have a large inventory of plastic spoons .Preparation and Conditioning Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Preparation and Conditioning Molding. We provide Preparation and Conditioning Molding service and we are professional plastic mold manufacturer. P&M are both a brand and a factory, with thousands of types of products, with high-quality service and quality as the first, Our main products is design and manufacturing of plastic mold, plastic product, metal product. Also, we do not have a minimum order quantity, tell us your needs, we can provide you with the most professional service.Plastic Logistics And Warehousing Moulding

For plastic logistics and warehousing moulding,NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. plastic logistics and warehousing moulding equipment includes:Plastic pallets, plastic storage boxes, plastic storage buckets, plastic shelves, plastic packaging boxes, plastic hoops, plastic palletizing racks, plastic pallet trucks, plastic sealing machines. We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Jigsaw Puzzle Molding

In today's toy market, Jigsaw Puzzle Molding are highly favored by consumers for their rich variety, diverse patterns, and excellent durability. Both children and adults can find fun and challenges in plastic puzzle toys. Plastic puzzle toys are widely popular, and manufacturers provide high-quality plastic puzzle toy molds to the market through exquisite technology and innovative design, meeting the needs of different consumers.Tissue Box Molding

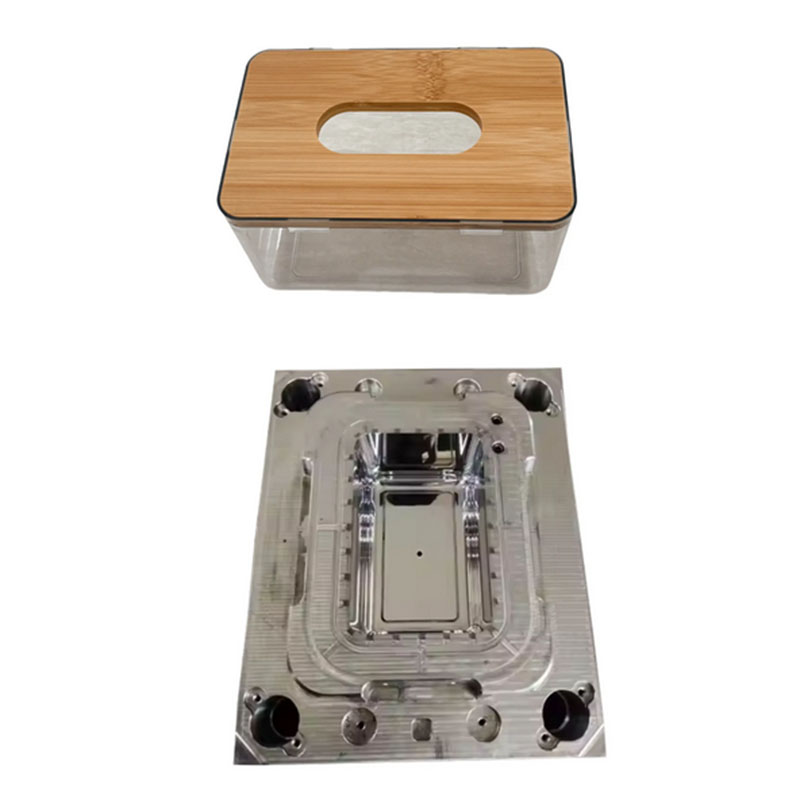

For tissue box molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Tissue Box equipment includes: Vertical tissue box, wall mounted tissue box, car tissue box, roll tissue holder, bound tissue box.We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Plastic Baking Tools Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Plastic Baking Tools molding. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. The Plastic Baking Tools have relatively high requirements for the Safety of materials. We usually recommend silicone, pp and some other plastics. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients. We will recommend suitable materials and professional design advice for our clients.