China Durable plastic spoons molding Manufacturer, Supplier, Factory

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for Durable plastic spoons molding, The continual availability of substantial grade goods in combination with our exceptional pre- and after-sales support ensures strong competitiveness in an increasingly globalized marketplace.

Durable plastic spoons molding, We now have a good reputation for stable quality products and solutions, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Hot Products

Car Front And Rear Covers Molding

For Car front and rear covers molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Car front and rear covers equipment includes: Front hood, engine hood, trunk lid.We mainly customize and make the casings of these machines, and we provide High-quality Car front and rear covers mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Plastic Egg Tray Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Plastic egg tray Molding molds. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. The Plastic egg tray Molding have relatively high requirements for the material softness. Usually We usually recommend silicone, rubber and some plastics. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.Microscope Moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize microscope moulding. We provide professional customized microscope mold services, and we are a professional microscope mold manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing microscope molds, our factory can provide one-stop service. We have design and production capabilities related to microscopes, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.Plastic Culture Dishes Molding

Ningbo P&M specializes in the manufacturing of Plastic culture dishes and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have positioned ourselves as a leading provider of top-tier Plastic culture dish solutions. As a specialized manufacturer, we comprehend the distinct demands of the Plastic culture dishes sector. By employing advanced technologies and precision engineering, we develop injection molds that yield impeccable Plastic culture dishes. Each mold undergoes meticulous crafting to guarantee precise dimensions, smooth finishes, and optimal functionality, aligning with the stringent standards of the industry.Plastic injection button moulding

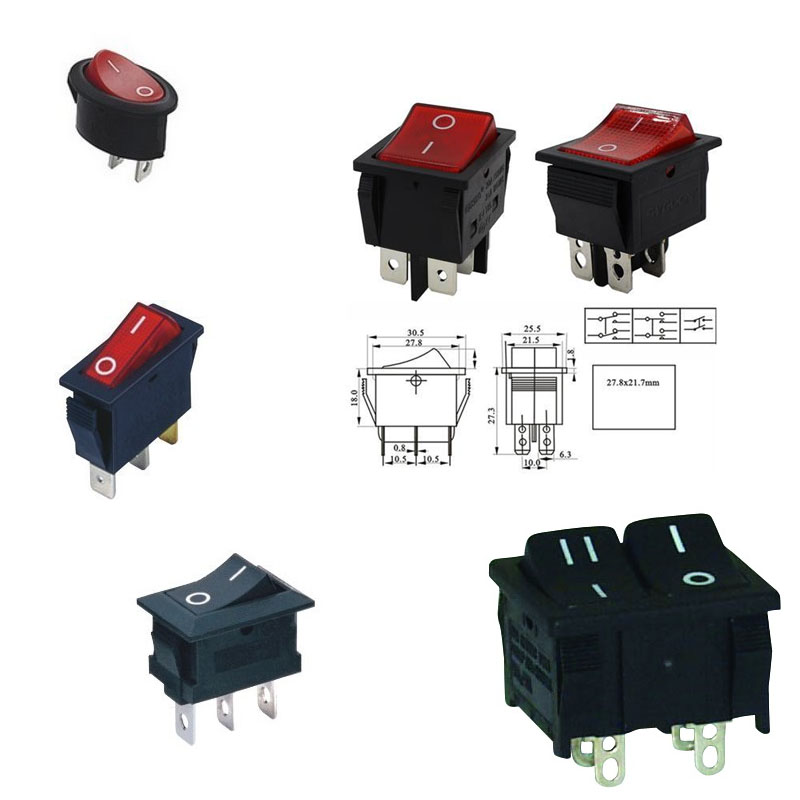

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize plastic injection button moulding. We provide professional customized plastic injection button moulding services, and we are a professional plastic injection button moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing plastic injection button moulding, our factory can provide one-stop service. We have design and production capabilities related to plastic injection button moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.Divided Parts Box Moulding

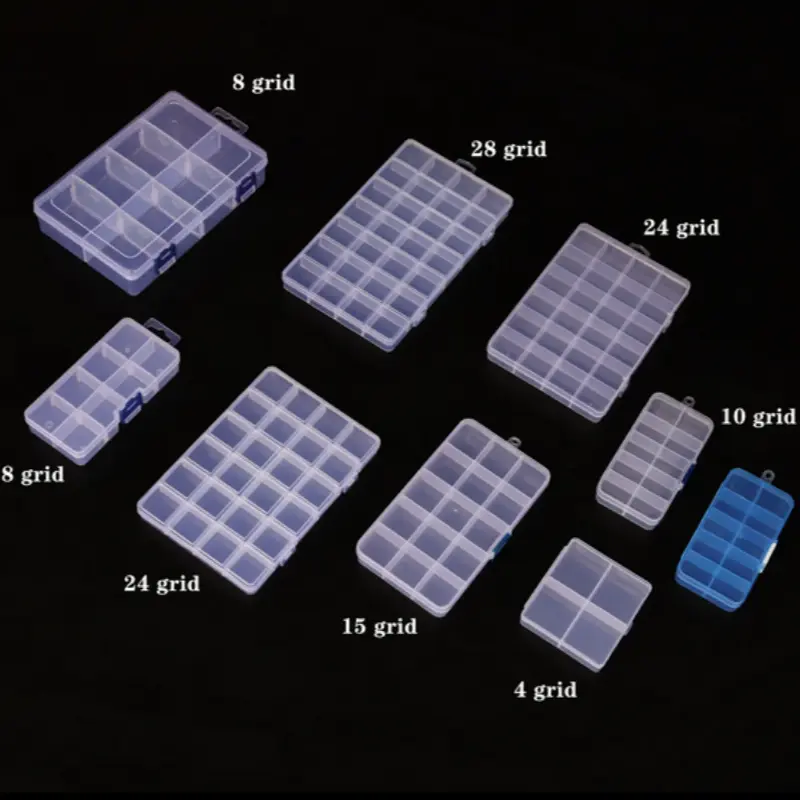

For divided parts box molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom divided parts box molding service, we are professional plastic divided parts box molding maker. We can use injection molding, blow molding, die casting and rotoplastic molding. We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology. As a professional manufacturer, we are willing to provide you with high-quality car logo injection molds. We will provide you with the best after-sales service and timely delivery. P&M Company mainly produces various types of injection molds for car logos. Welcome to contact us!