China Mold for injection molding Manufacturer, Supplier, Factory

"Control the standard by the details, show the energy by quality". Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for Mold for injection molding, We're going to empower people by communicating and listening, Setting an example to others and learning from experience.

Mold for injection molding, We have been in operation for more than 10 years. We have been dedicated to quality products and solutions and consumer support. We currently own 27 product utility and design patents. We invite you to visit our company for a personalized tour and advanced business guidance.

Hot Products

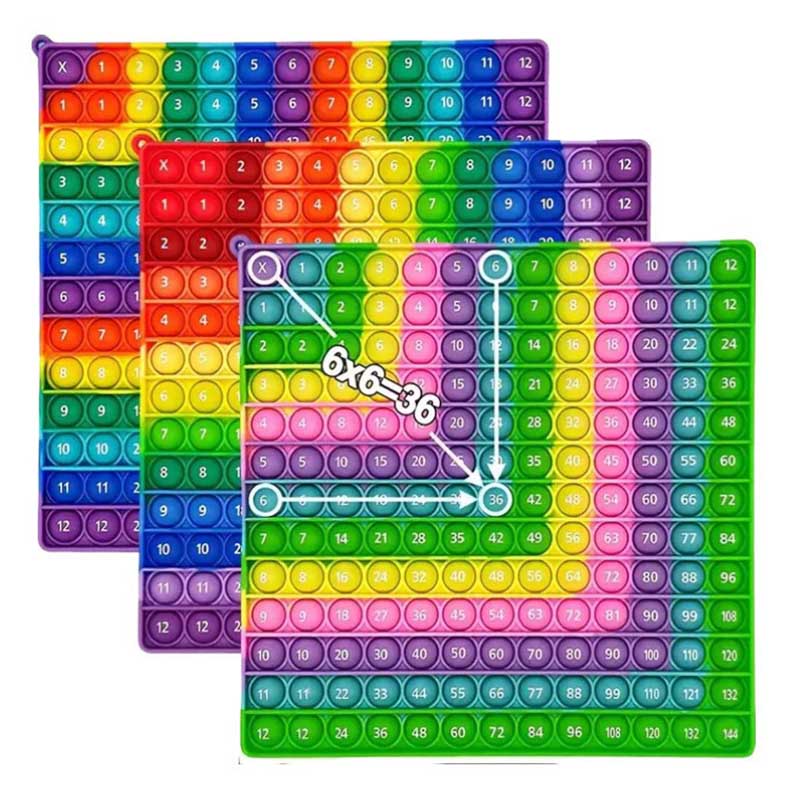

Digital Abacus Game Toys Molding

Digital abacus game toys occupy an important position in the children's toy market due to their unique puzzle solving ability. For children, digital abacus game toys can not only help them recognize numbers and learn simple calculations, but also exercise their hand eye coordination and logical thinking abilities. For more information on the Digital Abacus Game Toys Molding, please feel free to contact us.Cartoon Toy Molding

Cartoon Toy Molding plays a crucial role in children's lives. They bring endless joy and companionship to children with their vivid and lovely images, rich and diverse colors. Whether it's cute cartoon dolls or cool toy cars, they can stimulate children's imagination and creativity. Cartoon toys are not only tools for children's entertainment, but also play an important educational role in their growth process. By playing with cartoon toys, children can exercise their hand eye coordination skills, cultivate observation and attention, and also learn about colors, shapes, and other knowledge.Plastic Glue Gun Shell Mold

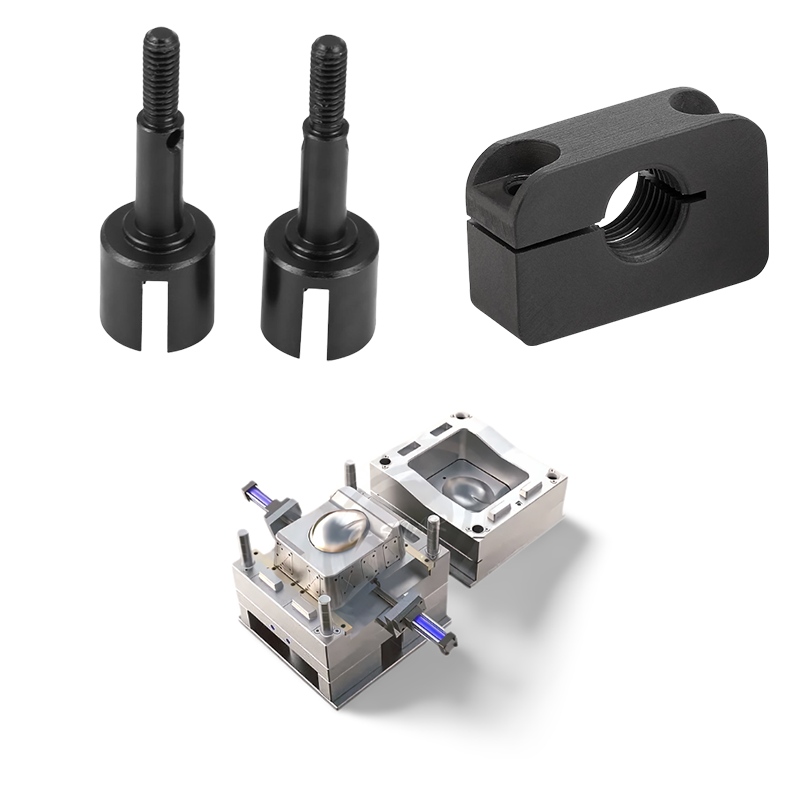

Ningbo Plastic & Metal Products Co., Ltd (P&M) is a specialized factory dedicated to the design, manufacturing, and processing of injection molds, boasting a rich history of over 15 years in producing Plastic glue gun Shell Mold. Our facility is well-equipped with more than 30 injection molding machines to deliver customized Plastic glue gun Shell Mold.36 Cavity Plastic Injection Moulding

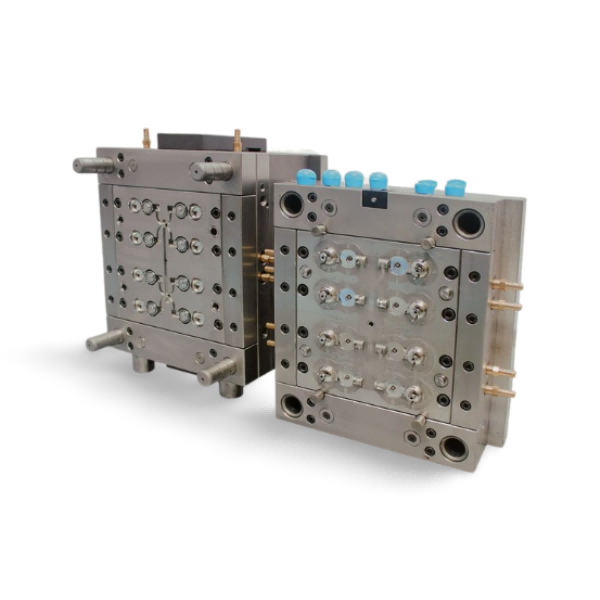

For 36 Cavity Plastic Injection Moulding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.Injection mold quote request

Ningbo P&M Products Co., Ltd,With deep expertise in injection molding, our company specializes in the high-volume production of precision custom injection plastic parts. We manage the entire process, from initial design and tooling to manufacturing and quality assurance, ensuring every part meets the highest standards of durability and accuracy.Injection mold tryout service

For Platic Injection Moulding Model, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.