China Mold for plastic component Manufacturer, Supplier, Factory

Our pursuit and corporation intention is to "Always satisfy our client requirements". We continue to develop and style remarkable high-quality items for each our outdated and new shoppers and accomplish a win-win prospect for our customers likewise as us for Mold for plastic component, Welcome to setup long-term romantic relationship with us. Best Value Permanently Top quality in China.

Mold for plastic component, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

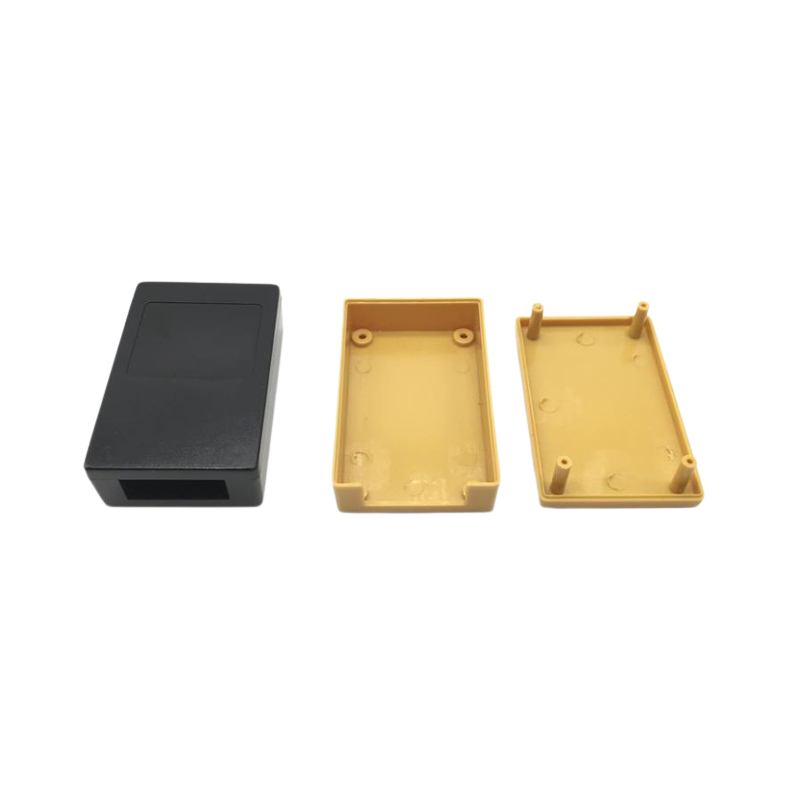

Hot Products

Plastic Combs Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Plastic combs Molding. We provide professional Plastic combs Molding service, and We have ISO 9001 certificates. Our company specializes in hairdressing air cushion combs, Plastic combs. We are professional plastic Combs manufacturer. Now we have 28 machines. our own mold opening machines, injection molding machines. Our service, product quality, and price are very advantageous. The products not only have exquisite craftsmanship, but also integrate fashionable design elements to find the perfect balance between practicality and aesthetics.Plastic Push Pins Mold Injection

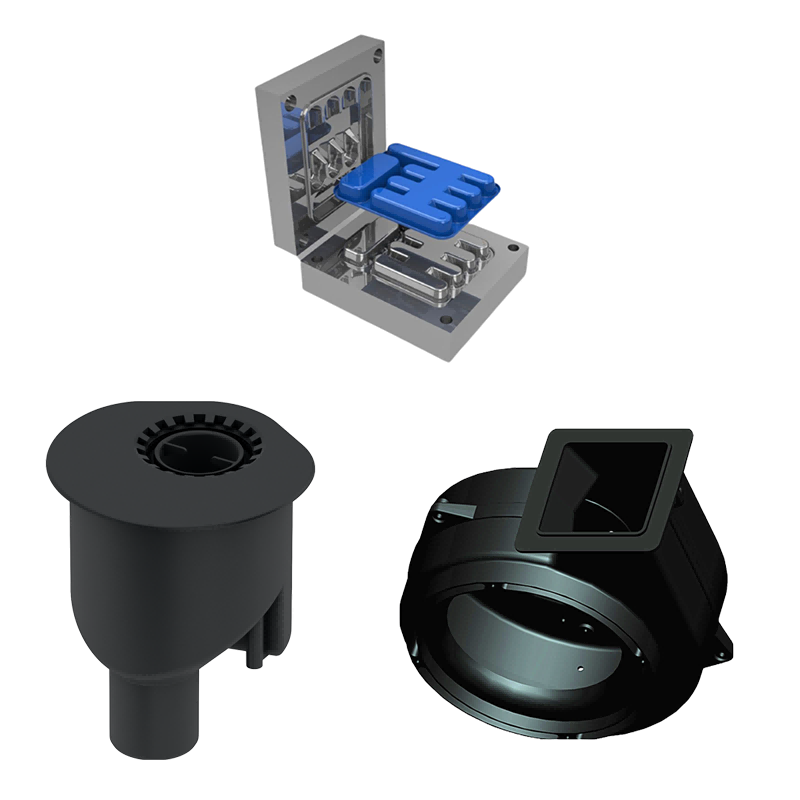

Ningbo Plastic & Metal Products Co., Ltd (P&M) is a factory specializing in the design, manufacture and processing of injection molds.We also have 30+ injection molding machines to provide you with customized injection molding processing services. We have 15 years of experience in working on Plastic Push Pins Mold Injection.No Punching Hook Molding

As a professional No Punching Hook Molding manufacturer and supplier, we provide customized service. In daily life, hole free hooks are everywhere and play an indispensable role. Whether in a cozy bedroom, hanging clothes and bags to keep the space tidy and orderly; Still in the damp bathroom, hang towels and shower balls for convenient daily use; Or in a kitchen full of fireworks, carrying spatulas and spoons, the kitchen countertop bids farewell to clutter, and the non perforated hooks quietly integrate into every corner of our lives with their convenient and practical characteristics.Mold for plastic switches

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Mold for plastic switches. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.Plastic injection tool and die maker

For Pmma Resin Pellets Injection Moulding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.Custom PU Parts

Ningbo P&M Products Co., Ltd,For decades,Welcome to P&M, a leading manufacturer with decades of proven expertise in the injection molding industry. We specialize in delivering high-quality, precision-engineered plastic components for a diverse range of global industries. Our core strength lies in our ability to handle complex projects and produce superior custom PU parts that meet the most stringent specifications. From concept to completion, we are committed to excellence, innovation, and building lasting partnerships with our clients.