China Plastic retainer mold Manufacturer, Supplier, Factory

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable goods for Plastic retainer mold, We welcome new and outdated prospects from all walks of lifetime to get in touch with us for foreseeable future small business interactions and mutual achievement!

Plastic retainer mold, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our merchandise, and we have been sure that we'll supply just what you want, as we always believe that your satisfaction is our success.

Hot Products

Magnetic Therapy Device Moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize magnetic therapy device moulding. We provide professional customized magnetic therapy device mold services, and we are a professional magnetic therapy device mold manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing magnetic therapy device molds, our factory can provide one-stop service.Operating Light Moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize operating light moulding. We provide professional customized operating light mold services, and we are a professional operating light mold manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing operating light molds, our factory can provide one-stop service. We have design and production capabilities related to operating lights, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.Eye Protection Device Moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize eye protection molds. We provide professional customized eye protection mold services, and we are a professional eye protection mold manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing eye protection molds, our factory can provide one-stop service. We have relevant design and production capabilities, including CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies.CD Player Molding

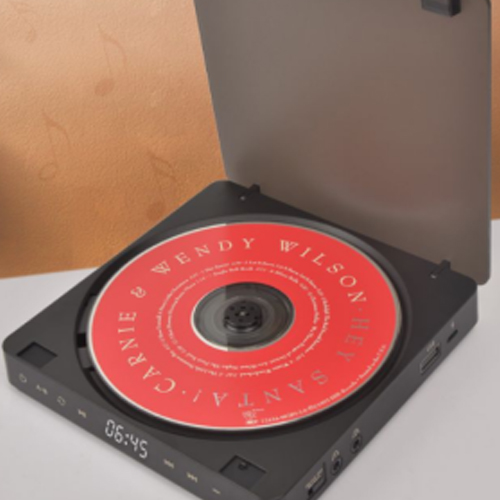

For CD Player molds, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.Black Pvc Injection Moulding

For Black Pvc Injection Moulding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.Mold lifecycle management service

For Plastic Injection Table Fan Moulding, Ningbo (P&M) Plastic Metal Products Co., Ltd. has 18 years of mold manufacturing technology and 10 years of export experience. We provide professional one-stop customized mold services and are a professional plastic mold manufacturer. We can use injection molding, blow molding, die-casting, and rotational molding.