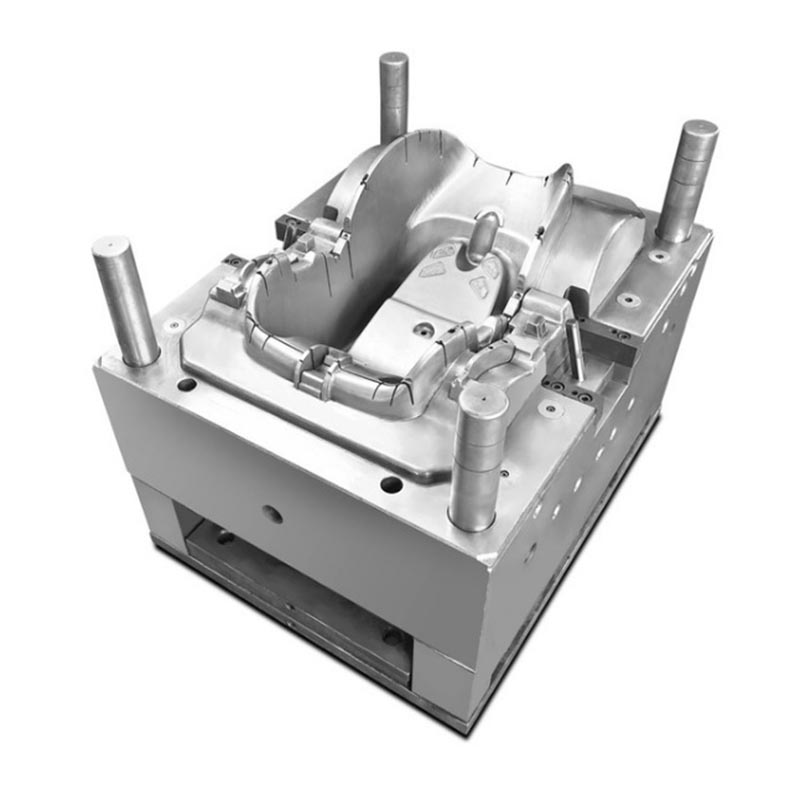

China Home Health Self-Testing Equipment Mold Manufacturer, Supplier, Factory

Every single member from our large efficiency profits team values customers' requirements and organization communication for Home Health Self-Testing Equipment Mold, In addition, we would properly guideline the shoppers about the application techniques to adopt our products and solutions as well as the way to select appropriate materials.

Home Health Self-Testing Equipment Mold, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we've better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We have been always here working for your demands whenever you want.

Hot Products

Car Roof Molding

For car roof molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Car roof equipment includes: Roof luggage rack, sunroof cover, antenna base cover, roof spoiler, roof wiper cover, roof antenna cover, roof windshield chrome strip, roof rail cover.We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Plastic Brackets Molding

Ningbo P&M specializes in the manufacturing of Plastic brackets molding and custom injection molds tailored for these components, showcasing exceptional expertise and advantages in this specialized field. With extensive experience and a strong commitment to excellence, we have established ourselves as a premier provider of high-quality solutions for Plastic brackets. As a dedicated manufacturer, we comprehend the specific requirements of the Plastic brackets sector. By leveraging advanced technologies and precise engineering techniques, we design injection molds that result in flawless Plastic brackets. Each mold is meticulously crafted to ensure accurate dimensions, smooth finishes, and optimal functionality, meeting the rigorous standards of the industry.Plastic Tray Molding

For plastic tray molding, NINGBO (P&M) PLASTIC METAL PRODUCT CO.,LTD. has 15 years of mold making technology. What we provide is Professional custom mold service, we are professional Plastic mold maker. We can use injection molding, blow molding, die casting and rotoplastic molding. Plastic tray molding equipment includes: Single sided tray, double-sided tray, grid tray, heavy-duty tray, stackable tray, foldable tray, breathable tray, non slip tray, food grade tray.We mainly customize and make the casings of these machines, and we provide High-quality mold manufacturing service for these products. These products require our Plastic mold design and manufacturing to be precise and of high quality. It is the embodiment of our mold technology.Acrylic Jewelry Box Organizer Mold

Ningbo Plastic & Metal Products (P&M) is a renowned plastic manufacturing facility based in Zhejiang Province, China, specializing in crafting premium injection molds for Acrylic Jewelry Box Organizer Molds. With a rich history of over 15 years in the field, we excel in the intricate art of designing and refining these molds.Assembly Toy Molding

The injection mold for assembling toys is the core link of the entire production process, which has a direct and critical impact on the final quality, appearance, and production efficiency of the toys.Welcome to wholesale high quality Assembly Toy Molding made in China from our factory. We will deliver quickly!Plastic Hat Mold

Ningbo Plastic & Metal Products (P&M) is a distinguished plastic manufacturing facility located in Zhejiang Province, China, specializing in the production of top-of-the-line injection molds for plastic hat molds. With over 15 years of experience in the industry, we excel in the intricate art of designing and perfecting these molds.