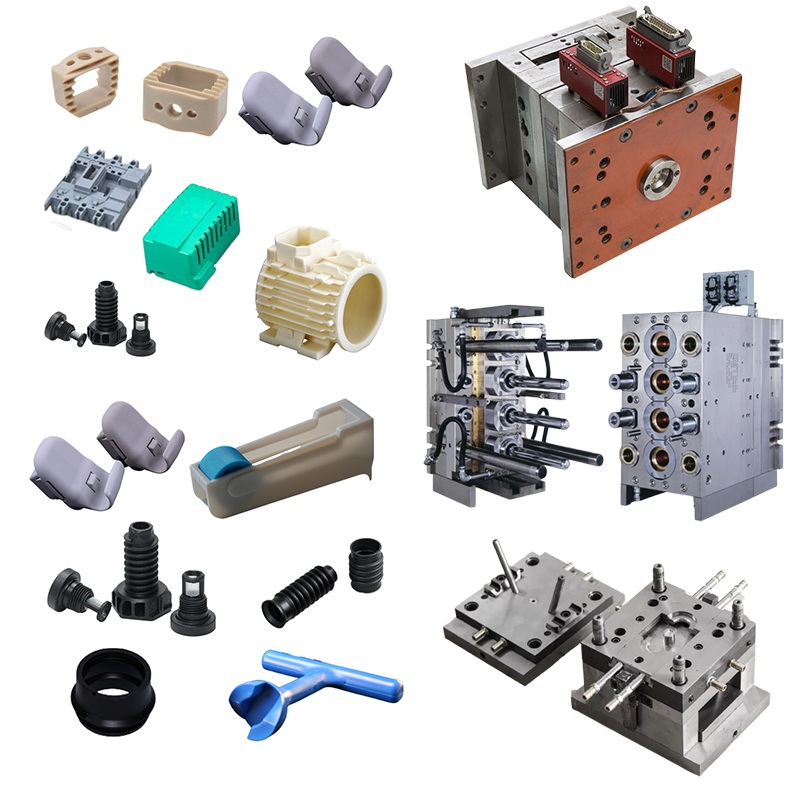

China Plastic adapter mold Manufacturer, Supplier, Factory

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for Plastic adapter mold, Let's cooperate hand in hand to jointly make a beautiful upcoming. We sincerely welcome you to pay a visit to our company or speak to us for cooperation!

Plastic adapter mold, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

Hot Products

Crate Molding

Our company focuses on the research and manufacturing of customized crate molding. With years of industry experience and advanced production technology, we provide high-quality and high-precision mold solutions for global customers.Our team has been deeply involved in the crate molding industry for many years, familiar with mold design and production processes for various plastic products such as turnover boxes, logistics boxes, and storage boxes. We are able to provide the best solutions according to customer needs.Travel Pet Bowl Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for Travel Pet Bowl Molding. We provide professional Travel Pet Bowl Molding service, and We have ISO 9001 certificates. we are professional plastic mold manufacturer. We have enough experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients. 90% Travel Pet Bowl of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has our own trademark and dozens of patents, providing more convenient technical support for mold making and product production.Medical injection moulding

Ningbo (P&M) Plastic Metal Products Co., Ltd. has 17 years of mold manufacturing technology and can customize medical injection moulding. We provide professional customized medical injection moulding services, and we are a professional medical injection moulding manufacturer. We have sufficient experience in selecting product raw materials and mold materials. In the process of customizing medical injection moulding, our factory can provide one-stop service. We have design and production capabilities related to medical injection moulding, such as: CAD design, mold manufacturing, injection molding, plastic product production, assembly and other technologies..Mini plastic pet toy Molding

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Mini plastic pet toy Molding molds. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. The Mini plastic pet toy Molding have relatively high requirements for the material softness. Usually We usually recommend pp, Rubber and some plastics. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.Plastic tube fitting mold

Ningbo (P&M) Plastic Hardware Products Co. has 15 years of mold making technology for customized Plastic tube fitting mold. We have ISO 9001 certificates. We provide professional custom mold service and we are professional plastic mold manufacturer. We have sufficient experience in product raw material selection and mold material selection. We are well aware of the properties of various materials and the advantages and disadvantages of mold design. We will recommend suitable materials and professional design advice for our clients.Threshold Molding

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and threshold moulding . We have our own engineer and factory, so that we can customer any plastic and metal products for our customer.